Trelleborg Sealing Solutions launches the H2Pro™ range of sealing materials for every application of the hydrogen value chain, including a new ethylene propylene diene monomer (EPDM) rubber for high-pressure environments across a wide range of temperatures and a unique thermoplastic polyurethane (TPU) for very low temperatures.

Solutions for the entire hydrogen value chain

Designed to accelerate innovation for sustainable technology, H2Pro™ has solutions for the challenges of hydrogen production, transport and storage, and end-use. Proven to withstand challenging application environments, the materials are suitable for high pressures, low temperatures, and resist permeation, making them better able to withstand rapid gas decompression while also demonstrating excellent wear and extrusion properties.

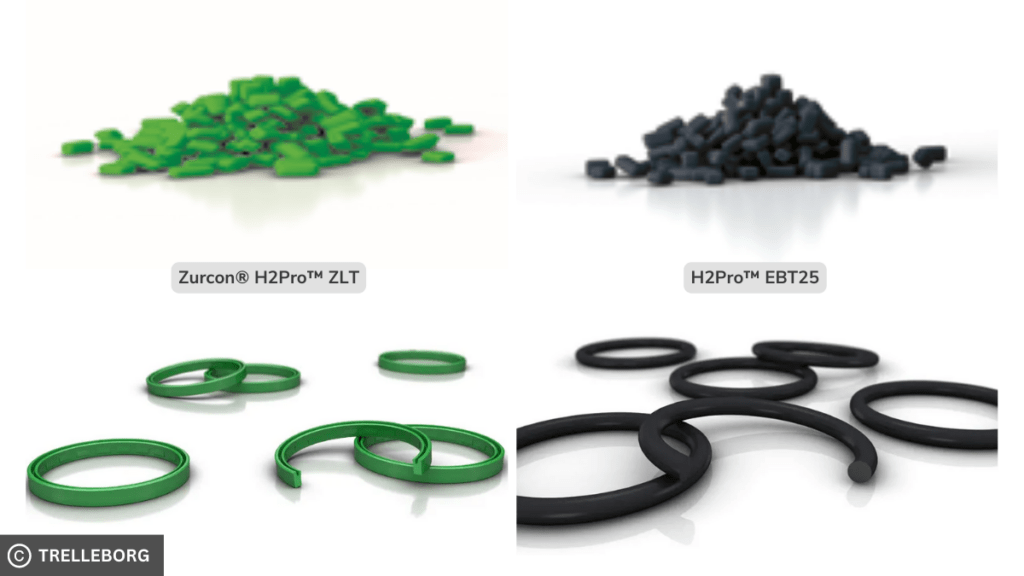

The range includes two new materials specially engineered for hydrogen applications. H2Pro™ EBT25 is a new EPDM for high-pressure environments across a wide range of temperatures, and Zurcon® H2Pro™ ZLT is a unique TPU for very low temperatures.

James Simpson, Global Segment Director Energy, says:

“Hydrogen has a major role to play in the transition to a carbon neutral world, both as a fuel source and as a storage medium for surplus energy from renewable sources. Due to its inherent characteristics, hydrogen is difficult to seal. The expanding H2Pro™ range, engineered by our advanced global R&D teams, offers reliable sealing solutions for a wide array of applications, including pumps, valves, connectors, and numerous other devices in the hydrogen supply chain.”

Sealing hydrogen – a tough challenge

The challenges include permeation and leakage, as hydrogen is the simplest element with the smallest molecular structure. Another is rapid gas decompression (RGD), where hydrogen in a high-pressure system can be absorbed into a seal. If the pressure in the system is suddenly relieved, gas trapped in the seal can expand, potentially causing the seal to blister and crack as the gas tries to escape. Finally, seals for different hydrogen systems need to withstand seriously tough environments, including high pressures of up to 1,000 bar/14.34 psi (for example, in high-pressure valves) and extremely low temperatures down to -250 °C/-418 °F (for example, in liquid hydrogen storage and transportation).

Simpson adds:

“Because it is so challenging to seal, Trelleborg is creating the materials and application-specific solutions to support every type of business involved in hydrogen, including those in the energy generation, aerospace, off-highway, truck and bus, CPI, chemical transportation and marine industries. As a longstanding global leader in polymer and elastomer solutions, we are ideally positioned to be their sealing partner of choice for hydrogen.”

Application-specific engineered materials

All H2Pro™ materials are designed specifically for excellent application-specific wear and extrusion properties and are validated to key industry standards in a range of challenging conditions typical of hydrogen environments. Trelleborg uses advanced testing rigs to assess materials for oxygen and ozone aging, hydrogen compatibility, leakage, permeation, and the ability to withstand RGD, and compliance with relevant international standards.

Zurcon® H2Pro™ ZLT has very low permeability and displays a superior ability to withstand RGD. It has a wide operating service temperature range, with outstanding low-temperature capabilities, displays excellent extrusion and wear-resistance properties, and is compliant with Regulation (EC) 79/2009, SAE J2600, and ANSI CHMC 2. It can be produced as O-Rings for static sealing on valves, filters, refueling nozzles, pumps, connectors, and fittings, and as U-Cups for static and dynamic applications such as valve stems, actuators, and regulators.

H2Pro™ EBT25 demonstrates a superior ability to withstand RGD, and features low permeability, a wide operating service temperature range, 85 Shore A hardness, and excellent extrusion resistance. It is compliant with Regulation (EC) 79/2009, SAE J2600 and ANSI CHMC 2, and can be manufactured as O-Rings for static sealing on valves, filters, refueling nozzles, pumps, connectors and fittings, and custom molded parts and frame seals for fuel cells and electrolysis equipment.

H2Pro™ materials are also available in a range of other compounds and seal profiles, including:

- Turcon® polytetrafluoroethylene (PTFE) and thermoplastic compounds for use as Varilip® lip seals

- V-Stack seals for use in static and dynamic applications with cryogenically compressed hydrogen and liquid hydrogen (LH2)

- FKM seals for blue hydrogen

- Lower-hardness EPDM compounds and silicone compounds for lower-pressure applications

- Metal seals for static LH2 applications

- Wear-resistant composite bearings and piston rings for compressor applications

IMAGE (above): Pictures of the H2Pro™ Hydrogen Sealing Materials. Zurcon® H2Pro™ ZLT (green) is pictured on the left, and H2Pro™ EBT25 (black) is pictured on the right. Credit: Trelleborg.